Engineers at the University of Exeter have developed concrete incorporating graphene. The new composite material is stronger, more water repellent and at the same time more environmentally friendly than traditional concrete.

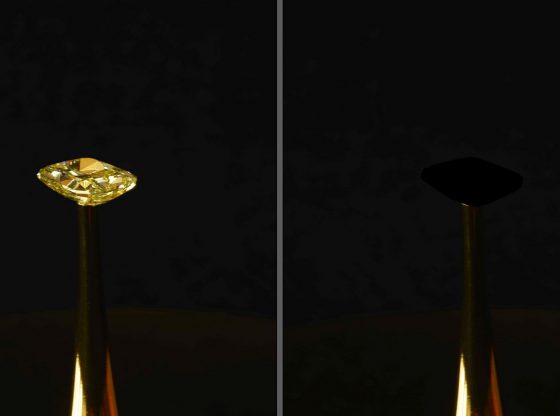

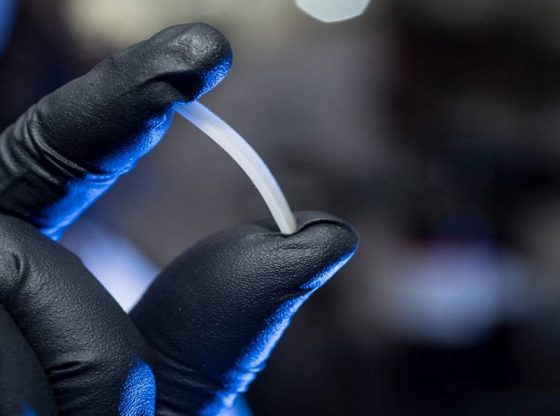

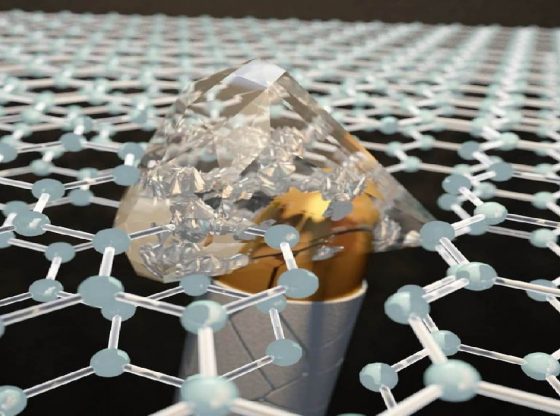

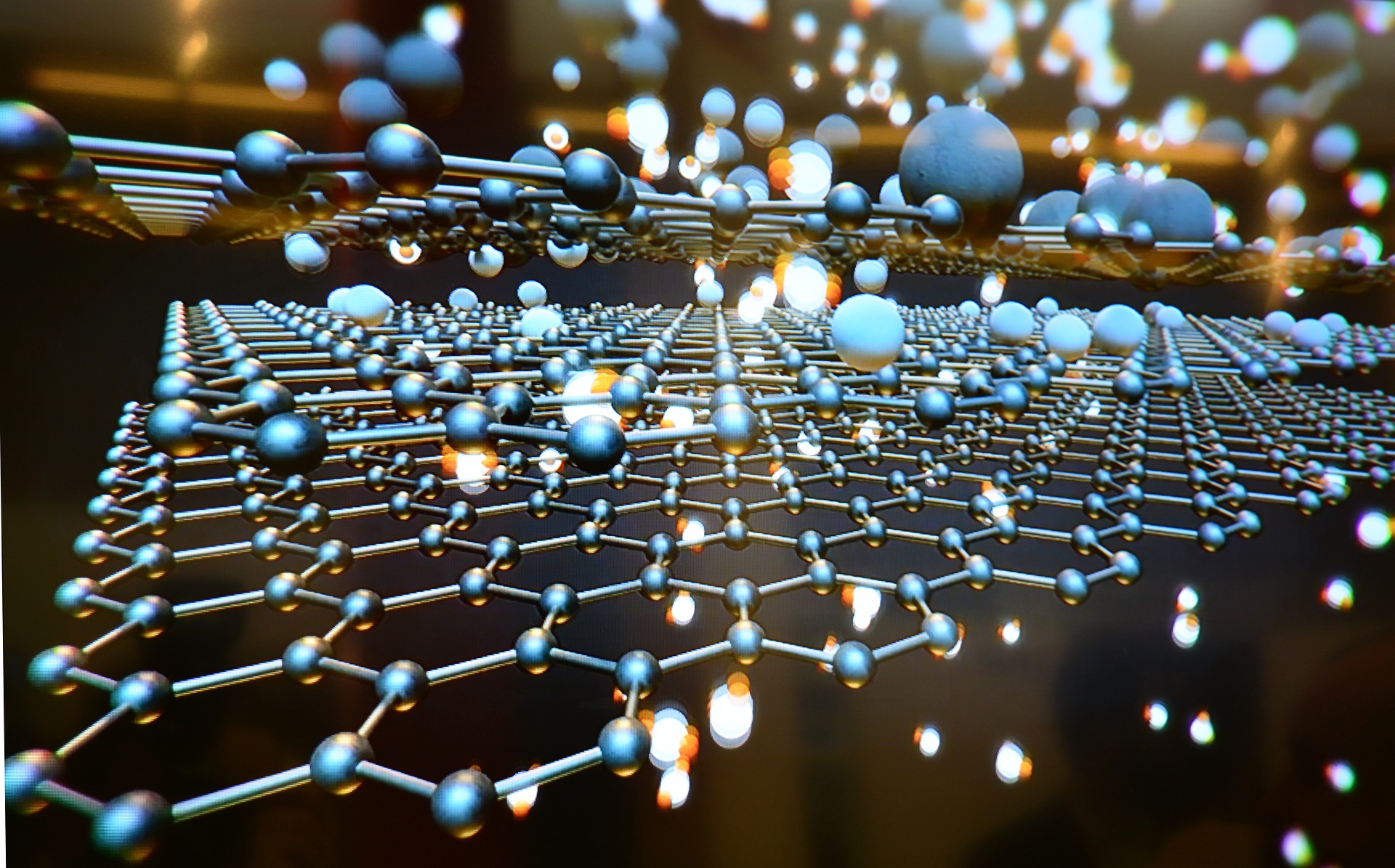

Graphene consists of a single layer of carbon atoms. It shares many similarities with graphite – but the atoms in graphene are arranged in a hexagonal pattern, which makes it extremely strong, yet lightweight and flexible. One square meter of graphene only weighs 0.77 mg.

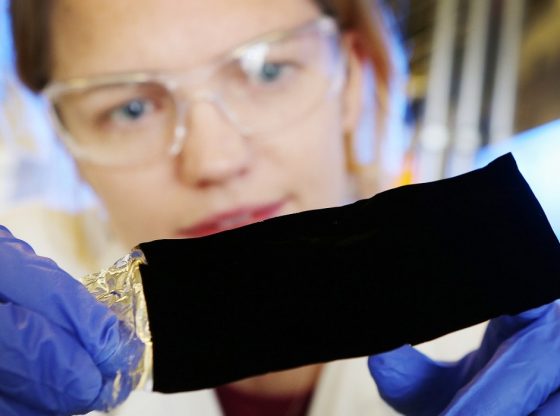

Now, engineers at the University of Exeter have incorporated the supermaterial into concrete. Mixing graphene with concrete has been shown to yield twice as strong building materials as traditional concrete, and four times as water-repellent.

Graphene powder is first ‘dissolved’ in regular tap water to create a graphene solution, which is mixed with cement and aggregates using typical processes seen on a building site. The graphene is uniformly distributed throughout the water and acts as a form of reinforcement to increase flexural strength and reduce deflection.

The technology harmonizes with EU standards and could, in theory, be used on construction sites immediately. Among other things, innovation can contribute to safer structures in demanding environments, such as earthquake-affected regions.

“This new composite material changes the playing field radically when it comes to reinforcing traditional concrete to meet these requirements. It is not only stronger and more robust – the surface also has a greater resistance to water. This makes the material uniquely suited for structures in areas that are difficult to access, requiring a lot of maintenance work”

– Professor Monica Cracium at the University of Exeter to Engineering and Technology.

Concrete production is one of the biggest sources of carbon dioxide emissions and a major advantage of graphene-reinforced materials are that the emissions are reduced radically.

“With the addition of the graph, we can reduce the amount of material required by 50 percent, which in turn leads to a significant reduction of 446kg per tonne of carbon dioxide emissions,”

– Professor Monica Cracium.

Now the research team hopes that their new concrete can be manufactured on an industrial scale, thereby reducing the environmental impact radically.

“Finding greener building methods is a decisive step forward in reducing carbon dioxide emissions in the world, and helping to protect the environment as much as we can,”

– Dimitar Dimov, one of the main authors of the Engineering and Technology study.

The University is in touch with research establishments to validate the results with a view to creating an industrial standard. “If all goes to plan, a product could be on the market by the end of the year,” Dimov concludes.

We have written about graphene for several years, the remarkable material that is both flexible and strong. It can be stretched out extensively without deformation, it is 200 times stronger than steel and has a conductivity higher than silicon.

Reference: