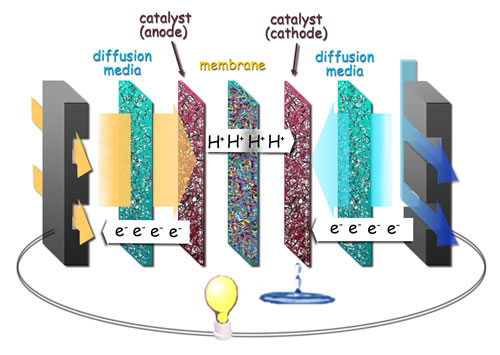

Hydrogen fuel cells can be compared to a battery, but unlike a battery it is fed by a tank of hydrogen (and oxygen from the air), producing electricity that powers an electric motor with only water vapor coming out of the tailpipe.

Cutting Costs with 90 %

Now, engineers at Toyota have managed to reduce the overall cost of fuel cell technology by more than 90 percent. They also estimate to cut those remaining costs in half when mass production begins next year.

The engineers also claim to have improved efficiency and solved several technical problems concerning cold starts and the lifetime of the fuel cells.

The engineers began by redesigning the fuel cells, making them simpler in design. Reducing the number of expensive materials needed to be used in production, such as platinum. The cold starts problem was then solved by returning heat into the system to dry out membranes in the fuel cells, making the vehicle able to start at minus 30 degrees Celsius.

Automaker Investments

Toyota is not the only automaker investing in hydrogen fuel cell technology, the South Korean company Hyundai claims to be the first to mass produce cars with fuel cells.

When they in February began production of the model ix35, production of which will increase during 2014 and 2015. Hyundai believes that with scaled production, costs are to be halved. Resulting from a combination of economies of scale, production and technology development.

Other companies, Honda, Mercedes, Nissan Ford, Audi, BMW and General Motors are all investing and aiming for mass production of hydrogen fuel cell cars in the years to come.

This adds to the recent news of hydrogen stations being built in numerous countries (Germany, Japan, South Korea, UK and US California). This would remove a major obstacle for hydrogen fuel cell cars to establish itself as a viable solution for the future.

Hydrogen Production

Another obstacle for hydrogen is for production to be environmentally friendly. You might think that with hydrogen being the most common element in the universe, and with all that water on Earth (H2O) – hydrogen would be abundant and easy to harness. But in reality on Earth, we are forced to often use dirty and inefficient methods of hydrogen production. S

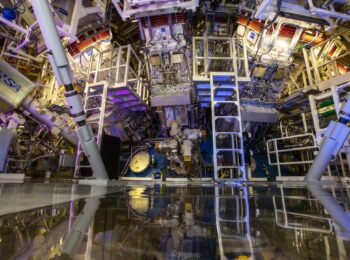

The most common methods presently used for hydrogen production from water are different forms of physical separation; steam reforming from hydrocarbons, electrolysis, and thermolysis. Steam reforming requires heat and we need to use energy to achieve energy (hydrogen).

A promising clean method to produce hydrogen is biohydrogen. This is hydrogen produced biologically, by algae, bacteria or archaea. Another clean method is to use only sunlight and water, see more information below.

Water is indeed essential for life. But as a source of energy, water could also be essential for human civilization. From water to hydrogen, to energy and fuel for our transportation – with water vapor as the only by-product. A clean cycle of water. Science fiction today but could indeed be a promising and optimistic science fact in the future.

_______________

http://www.fuelcelltoday.com/

Efficient Generation of H2 by Splitting Water with an Isothermal Redox Cycle

______________________________